- Concept to Production Electronics since 1985

Conformal coating for performance in extreme environments

Conformal coating is a widely used process in the PCB industry to add environmental protection to components that will be operating in harsh environments, such as in humidity, corrosive gases, sandy areas and much more. Nemco provides conformal coating in three ways, depending on the needs of the PCB. We have two purpose-built conformal coating rooms in our facility. This ensures we can supply PCBs for every application and remain the supplier of choice for so many businesses.

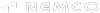

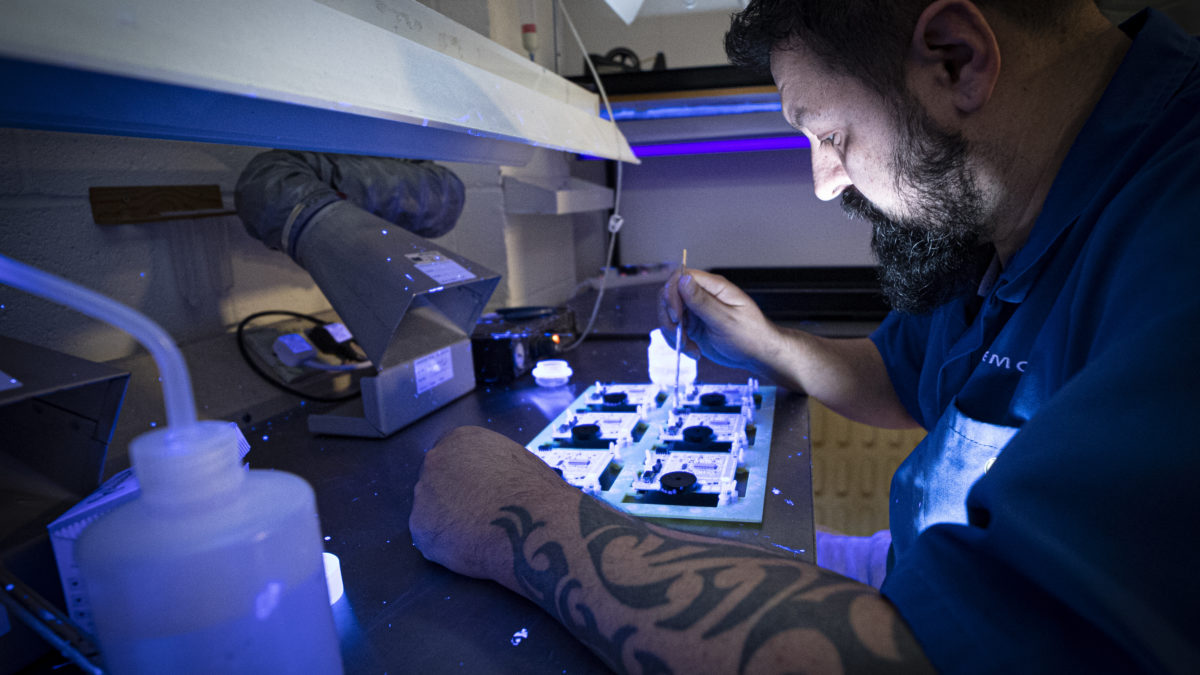

One room applies silicon material to the PCB and the other acrylics. Each room has its own inspection equipment and UV lighting setup, ensuring the operators can fully inspect each board to ensure a perfect coating. With three machines providing different types of finishes, we cover every base.

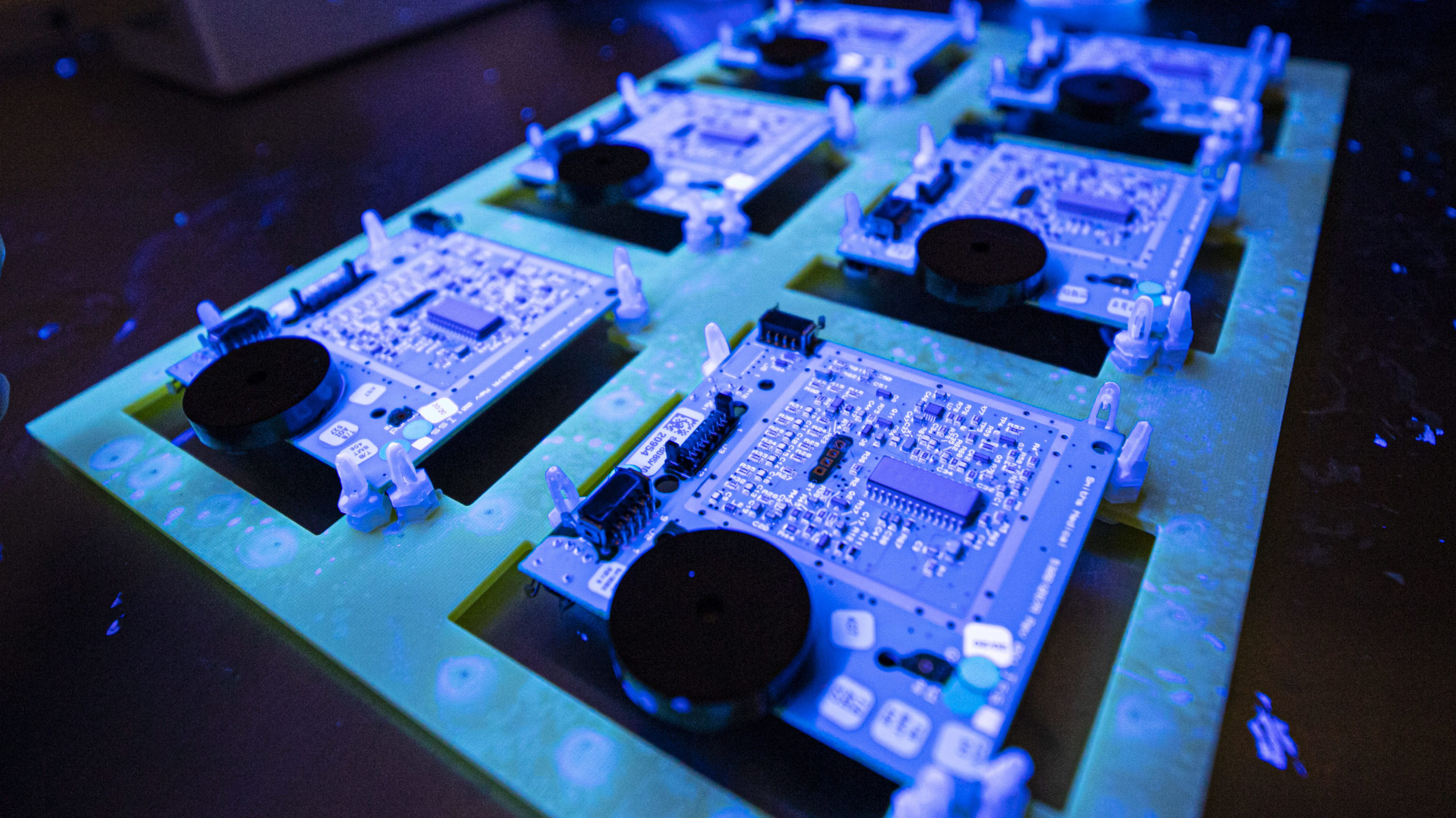

Acrylic selective spray coating

The Acrylic room contains a Nordson Asymtek SL940 – a selective spray coating machine which is designed to deliver the highest standard of coating and efficiency. It produces consistently excellent results with a uniform coating and extremely high accuracy. All process parameters are traceable and stored in software, eliminating the need for labour-intensive board masking. The machine can be carefully programmed to ensure it coats the correct areas as needed – correct thickness is achieved in a single pass with little and with virtually no overspray.

Certonal coating with silicon

Our Certonal Coating is undertaken by a state-of-the-art Autocoat 1000 dip coating system, which fully immerses the board and then moves it into a cooled, frost-free drying area contained in the same tank. Certonal coating provides excellent protection for boards against humidity and condensation. This method of coating does not require any masking, as components maintain all their functionality when coated in silicon.

RDC 15 FSC coating

The RDC 15 dip coater is a highly programmable dip coater for applying silicon coatings. A variety of speeds and settings can be assigned, including a dipping speed which can be finely adjusted. Both the dipping and drip off times can be adjusted independently, to ensure that the perfect coat is achieved with every board.

Exacted down to the micron

After the coating process is complete, our skilled operators undertake testing using an advanced measuring systems that allows us to measure down to individual microns of thickness, with a standard coat of acrylic being 30-120 microns, and a standard coat of silicon being 50-210 microns. This ensures that every single board leaves our facility with the perfect coat, to function exactly as intended.

Partner with Nemco for your PCB manufacturing

Our range of conformal coating machines ensures we can supply PCBs for every use case. If you are looking for PCB manufacturing with conformal coating, talk to our team today and find out how Nemco could transform your supply chain. You can also follow us on LinkedIn for the latest updates.