SECTORS

Medical & Labratory

Nemco’s full-service Contract Electronics for medical and labratory

Nemco has served the medical sector for many years, with our expertise being relied on when it mattered most.

Our state-of-the-art facilities enable us to produce for these critically important projects, such as helping to supply ventilators in the Covid-19 pandemic. We understand the need for the highest standards of quality and service to successfully serve this sector.

Helping pioneer medical innovations

At Nemco, we are proud to have a long history of partnering with pioneering medical and laboratory equipment companies. For decades, our capabilities and experience have supported customers across the entire product development journey – from early concept to volume manufacturing. Nemco’s state-of-the-art facilities enable us to support the complete journey from concept to production.

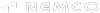

Our expertise in medical technology runs deep. We understand the unique requirements of components destined for critical medical settings. Rigorous quality control and our on-site testing facility ensures our parts consistently meet the highest standards of reliability and performance.

Delivering when it matters most

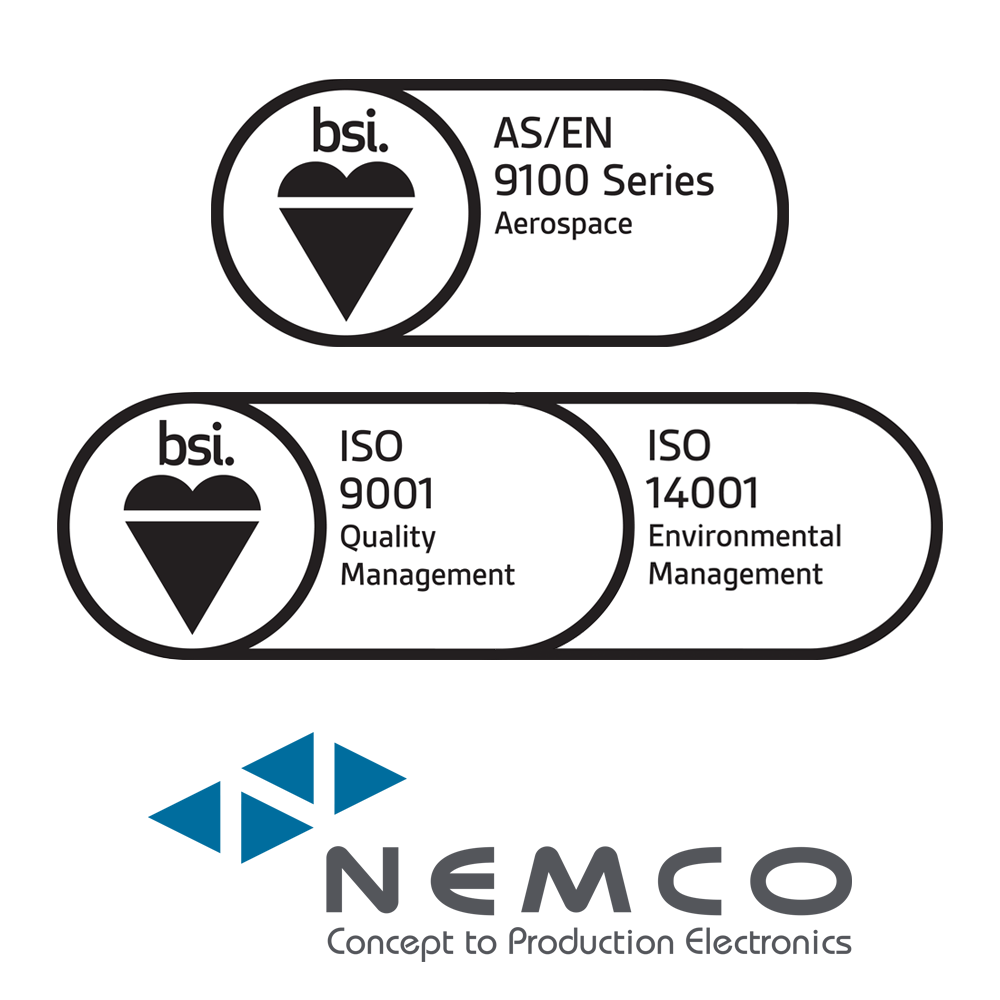

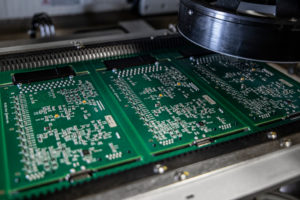

Nemco understands the critical role that the medical sector plays and the importance of ensuring the highest standards are met. This was demonstrated clearly during the UK Ventilator Challenge. Faced with surging national demand for ventilators during the Covid-19 crisis, Nemco rapidly designed test equipment and manufactured over 24,000 PCB assemblies under extreme time pressure.

Our agility and commitment to quality was crucial in equipping the NHS to save lives when it mattered most. We are proud of our work in the medical sector and have shown we have what it takes to deliver, even under extreme pressure.

Customer-focused quality

With comprehensive services including design support, prototyping, and assembly of complex PCBAs, we enable medical innovations to advance from ideas into reality. Our culture of continuous improvement means we are always ready to take on new challenges for the medical industry as technology evolves.

This same dedication and flexibility defines our work with every customer, large or small. With ISO 9001, 14001 and AS9100 certification affirming our rigorous quality management system, customers can trust Nemco to deliver components suitable for the most sensitive and critical medical settings.

We see our role as a partner, not just a supplier. Our knowledgeable engineering team draws on decades of experience to provide valuable guidance and feedback to customers, improving outcomes and accelerating time-to-market.

Take the next step in your medical project with Nemco

If you are looking to advance innovation in medical devices or laboratory equipment, leverage Nemco’s expertise and take your project to the next level. Contact us today to learn more about our full range of design, testing, and manufacturing services.

You can keep up to date with the latest developments from Nemco on LinkedIn.

Testing taken to the next level

We take pride in everything we do, maintaining specifications through regular inspection and testing. Nemco offers highly advanced inspection and testing facilities on site, couple with our dedicated team, who are all cross-product trained and have a huge wealth of experience within the field of electronics test. Advanced in-house testing capabilities including RF, ionic contamination, and environmental stress screening ensure durability and performance of aerospace and defense electronics.

Continuous improvement in our class-leading quality

Nemco continuously invest in the latest technologies and training to maintain our class-leading status and ensure we deliver to the highest standards first time, every time. As aerospace and defence require durable and reliable electronics for critical applications, Nemco maintain a dedicated cleanroom for assembly and testing as well as electrically-insulative coating facilities.

To achieve consistent quality of manufacture, we have on site our own vastly experienced IPC certified instructors who conducts training and competence assessments for our manufacturing staff to IPC-A-610, IPC-A-620 and where required IPC-A-600. This ensures quality is inherent throughout the business.

Critical application capabilities

Cleanroom

Our Cleanroom measures 6Mx6M and operates under the BS EN ISO 14644-1:2015 cleanroom standard, it has a classification of ISO 7 which means that the air drawn into the room using HEPA (High Efficiency Particulate Air) filtration, provides a controlled environment for airborne particles and changes between 60 and 90 times per hour.

The cleanroom provides a production environment with controlled airborne contamination which is essential for a wide variety of electronic, optics and other critical manufacturing assemblies to ensure that sensitive products are not harmed during the manufacturing process.

Conformal coating

Conformal coatings are widely used in the electronics industry for environmental protection of PCBs from humidity, corrosive gases and solvents, dust, sand, and other contaminants.

At Nemco we have two purpose built, ventilated Conformal Coating rooms, one used for the application of Silicon material and the other for Acrylics. Each of these rooms contain their own spraying equipment machinery, tooling, and material storage.

Trusted by so many for PCBA

With a dedication to understanding our customers’ unique needs, Nemco delivers exceptional service, quality, and on-time delivery.

We aim to continually exceed expectations and serve as a valued outsourcing partner. That is how we have built up such a loyal customer base who trust Nemco to deliver for them.

For 40 years, companies have relied on Nemco’s experience in aerospace and defence Contract Electronics Manufacturing. Learn more about our capabilities and industry certifications. Contact us today to discuss your specific project needs.

Prototyping service

Nemco provides full-service prototyping to help you evaluate design concepts, validate functionality, and accelerate time-to-market. Our experienced engineers can offer early involvement in your project to help us fully understand your requirements and design a product that exceeds expectations. We provide feedback on proposed designs and manufacturing processes to ensure the best possible solution is found.

Our prototyping capabilities span basic hand assembly to advanced BGA and odd-form component placement using the latest machine assembly. Test options are reviewed early on to implement efficient production testing.

Transform your supply chain with Nemco

Nemco are the ideal partner supplier and OEMs in Aerospace and Defence. If you are looking for a full-service PCB manufacturer you can rely on, talk to our team today and find out how Nemco could transform your supply chain. You can also follow us on LinkedIn for the latest updates.

Delivering highly reliable products to customers across the globe.

DESIGN

We provide a full product development service, working closely with clients at all stages from initial concepts through to full volume manufacturing.

PCB ASSEMBLY

The leading UK Contract Electronics Manufacturer providing a complete product manufacturing, logistics and repair service to our customers.

BOX BUILD

Technically advanced and complex products are manufactured, tested and configured then packaged and shipped Worldwide from our UK facility.

SUPPLY CHAIN

Our Success has resulted from a number of factors, in particular, our flexibility, technical skills and reliability in meeting our customer’s needs.